連續兩年寫作不間斷,可以稍微自稱是個「文字堆砌人」。曾於多領域任職與創業,帶隊完成金氏世界紀錄項目挑戰。現音樂產業 x 文化活動產業與夢想家共同追逐獨角獸中。

The genetic difference between good and bad products

After a busy afternoon, if you find a lot of things to fill up your time, whether you are in a Lock down state or not, or a group management similar to the current Semi-Lock Down appeal in Taiwan, you can always find many things in your own place. things that can be done.

Perhaps it was also the reason for the lock down. The siblings who lived under the eaves moved their minds about some of the furniture that was lacking in the house, so they bought a cabinet of their own and came back to the house. It is always annoying to see two heavy boxes of goods piled up every day in the places where I walk around every day, so I came to combine them on a whim.

In the past, no matter where I was in the past, when I needed to buy some simple furniture for a house, I would always go to ikea for a walk. Although everyone around me always criticized it endlessly, I still fell in love with ikea's quality and dazzling selection. So from a small square to a whole set of bed frames, I bought it from ikea and assembled it myself. You can also experience some fun from it.

Last year, taking advantage of the short time I returned to Chengdu, I took the opportunity to replace another set of mattresses. As a result, the mattress was sent to the old bed frame by the master who happily asked the master to put it on the old bed frame, only to find that the old bed frame, although it was also produced by ikea, was actually a strange size because of the age. New mattresses just don't fit in perfectly.

This is embarrassing. After a few days, I found a set of solid wood beds in muji. At that time, the salesman "very strongly" suggested that he spend a little more money and let the installer directly assist the assembly. He said that it took several big men more than four hours to complete the assembly. But I love challenges, so I want to try it myself.

With the experience of assembling these furniture, I don't think there will be any difficulties in the combination of this cabinet. Unexpectedly, it was so naive.

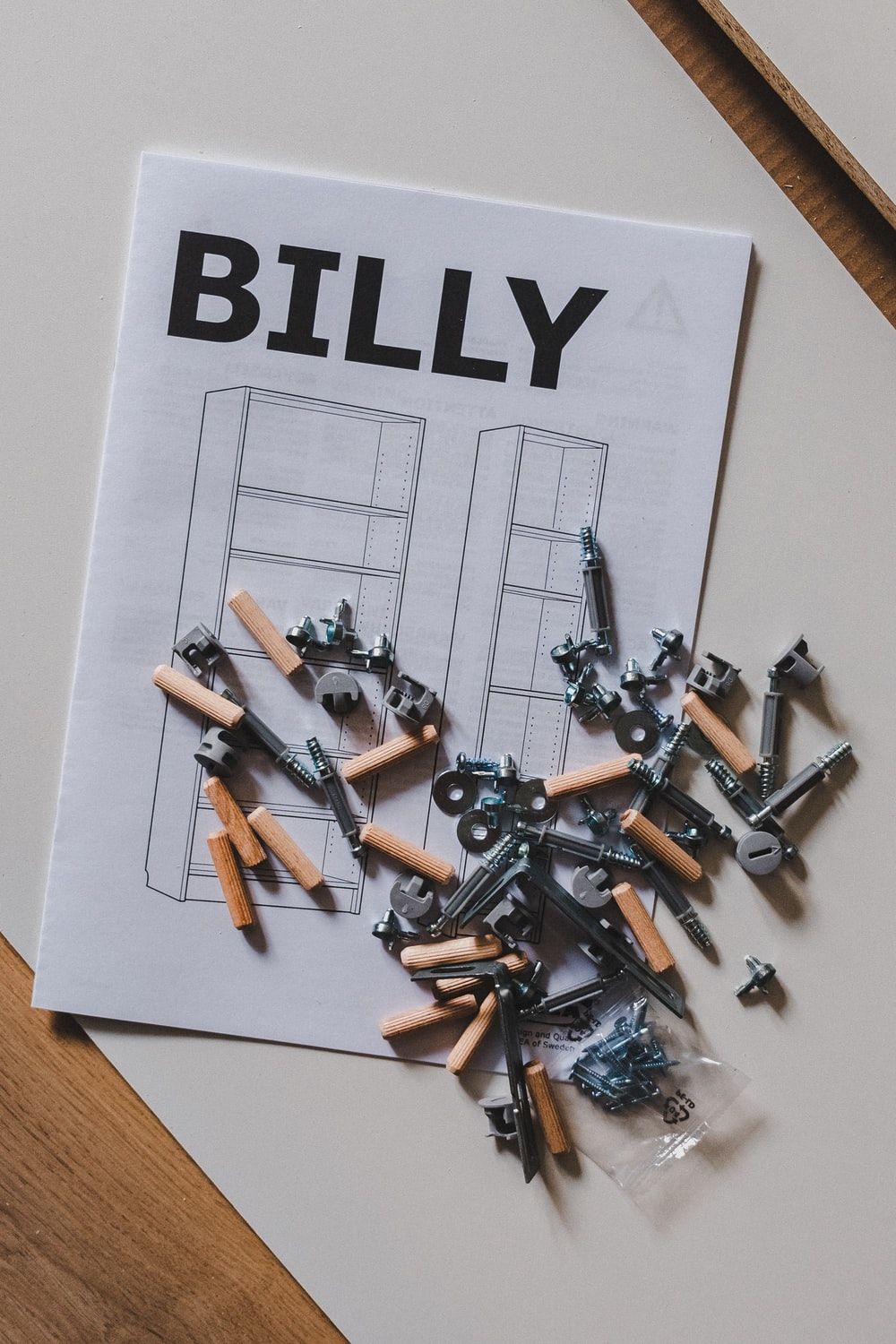

After disassembling the two large boxes of hardware parts and plates, I compared it with the list according to my habit, and then started to move forward step by step. Only then did I find that ikea can provide products of almost the same quality on a global scale, and use the most simple and basic tools, as little text and more pictures as possible for assembly introduction, which seems to be an inconspicuous standard. It seems quite difficult.

The manufacturer of this cabinet is not well known. After opening the box, I feel that although the quality of the board is not unusual at first glance, the details of some edges and corners are full of flaws. For example, the edges of the combined version will inevitably have collisions during transportation or in the production process. If the quality does not meet the standard, such collisions can easily be amplified. Every ikea box will be stacked with almost no space inside. In addition to reducing the shipping volume, it can also reduce the defects of the material inside due to movement and shaking during the transportation process. Not to mention that ikea offers a return guarantee.

Forget it, I want to say that during the epidemic, don’t ask too much for details, and start pretending all the way. Although it is also assembled by screws, stakes, tenons, etc., whether it is possible to reduce the difficulty of the user's combination and ensure the rationality of the assembly process from the design side is also clear. There will be many steps in the installation of the cabinet, which must be combined in an unergonomic posture. Some things that are done in the steps are found to be unnecessary in the next few steps. That's it.

Although these logical inconveniences do not affect too much, they will cause a lot of blows to the mood during the assembly process. Just before watching the hardware parts disappear bit by bit and close to completion, a low-level and fatal design flaw occurred.

The parts that should be installed in a certain step are in conflict with the parts in the previous step. If the things to be installed later are combined according to the holes on the plate, they cannot be installed. The two parts should be placed on the board. If there is no conflict, the hole position is simply wrong.

Having this problem in nearly 95% of installations, it doesn't seem to help to call to complain. So I can only use the awkward and uncomfortable posture again, mark the hole position in the non-conflicting position, and then use the screw to "wash" a new hole position by myself.

In the end, the cabinet was assembled in a state full of flaws and imperfections. Stability and security, I feel that there is no problem. But it is the serious flaws in these designs and the inconvenience in the assembly logic that make the whole assembly process without a happy sense of achievement after the end. Instead, it was full of distress.

Sometimes I think that the reason why a brand can become famous all over the world is not necessarily just piled up through many bright and bright advertisements on the surface, but a lot of DNA deep into the product will allow users to truly experience whether they are attentive and more able. Make your own likes and dislikes about a brand.

Like my work?

Don't forget to support or like, so I know you are with me..

Comment…