The Importance of Duct Temperature Sensors

1. The role of the duct temperature sensor

Duct temperature sensor is used to measure the temperature of the liquid or gas in the pipeline, belongs to a very important sensor in the field of industrial control. Its measurement data is widely used in industrial control and safety protection.

2.Classification of duct temperature sensors

Duct temperature sensors are divided into contact and non-contact according to the measurement principle. Contact sensors need to directly contact the measuring object, so the condition of the surface of the measuring object and the material has certain requirements, but the measurement accuracy is high. Non-contact sensors use infrared light and other measurement methods for measurement, do not need to contact the measuring object, has the advantages of fast measurement speed, wide range of applications.

3. Key points in the selection of duct temperature sensors

①Measuring range: According to the actual situation to choose the appropriate measuring range, must be consistent with the characteristics of the measurement object and process requirements.

②Accuracy: Measurement accuracy is one of the important criteria for measuring the performance of the sensor, which is related to the reliability and accuracy of the measurement data.

③Response time: Response time is the time from the beginning of the sensor's reaction when it detects a change in the detected object to the output result. For some processes that need to be adjusted in time, the response time is very important.

④Environmental Adaptability: The environment of the industrial site is complex and changeable, the sensor has to work in different environments, so it should have a certain degree of adaptability, such as the ability to resist high temperature, corrosion and so on.

⑤Installation Method: The installation method of the sensor is also one of the important selection factors, and the appropriate installation method should be selected according to the actual situation.

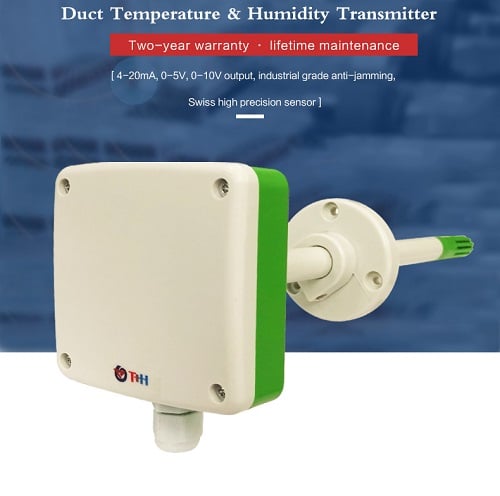

4. Why we need industrial duct temperature and humidity sensor:

①The industrial pipeline temperature and humidity transmitter can monitor and record the temperature and humidity changes in the industrial environment in real time. This is very important to grasp the state and trend of the production environment, which helps to early warning and take appropriate measures.

②Temperature and humidity are critical parameters in many industrial processes. Industrial duct temperature and humidity sensors can provide accurate measurement data to help realize precise process control and regulation, ensuring the stability and consistency of the production process.

③Certain industrial production processes have strict requirements for temperature and humidity, and the use of industrial pipeline temperature and humidity transmitters can ensure that the temperature and humidity in the production environment meets the required standards, thus ensuring product quality and consistency.

④In some industrial environments, excessively high or low temperatures and humidity may have an impact on the safety of personnel and equipment. Industrial pipeline temperature and humidity transmitters can detect abnormal temperature and humidity conditions in a timely manner and trigger alarms or take appropriate measures to ensure safe production.

⑤Industrial duct temperature and humidity sensors can help staff record temperature and humidity data and transmit it to a data logging system or monitoring system. This data can be used for subsequent data analysis, trend prediction and quality improvement to help optimize the production process and improve efficiency.

5.Summary

Selecting the proper duct temperature sensor can guarantee production safety and improve production efficiency. Before selecting the type should be based on the actual situation to fully consider the various factors, choose the right type of sensor, so as to improve production efficiency and equipment stability.

喜欢我的作品吗?别忘了给予支持与赞赏,让我知道在创作的路上有你陪伴,一起延续这份热忱!