【Construction life】Reinforcement material list check 3-beam reinforcement check

Beam reinforcement checking was the biggest job I did when I first came out of the society. Interestingly, at that time, a senior who had worked for more than 20 years still could not understand the beam reinforcement construction drawings. I hope you who read this article, don’t become this. kind of people.

The construction sequence of the raft foundation is: plate→column→beam. After the concrete is poured and the formwork is assembled, it is the BS version commonly known as the water tank cover, also known as the "raft foundation top plate". , you can take a look at the first two articles and put them below for your reference.

- [Construction Life] Reinforcement material list check 1-version reinforcement check

- 【Construction life】Reinforcement material single check 2-column reinforcement check

Check steps

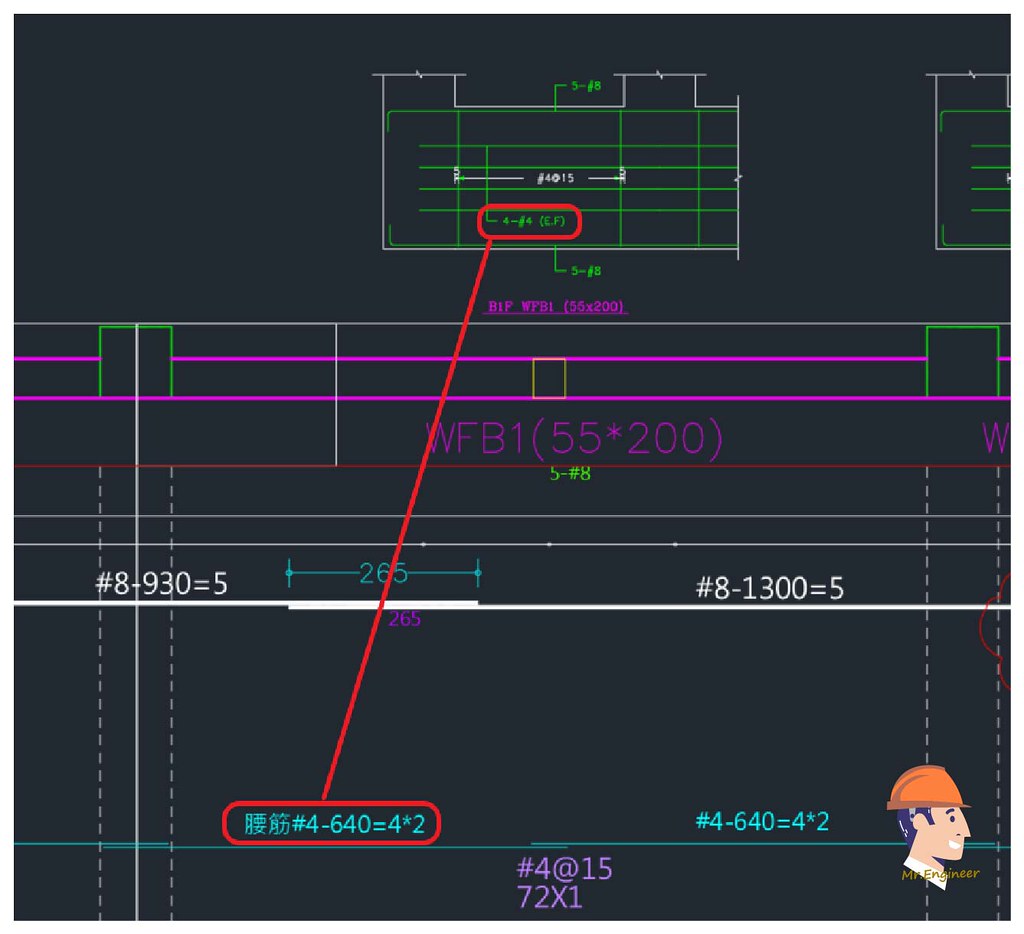

We can see that there is a number at the position of the red circle in the figure below. That number corresponds to the position of the entire row of horizontal (or vertical) beams. The number of the structural drawing is that there is a beam in the middle of the two pillars, but the construction drawing has a continuation. When answering a question, it will be drawn from the beginning to the end, and will not be truncated in the middle. This is what we need to pay attention to when interpreting.

After knowing the rules, when you go to the corresponding structure diagram, it will not be too noisy (such as walking on the construction site for 20 years is less likely to happen, there is no way that people are relatives of the royal family, and social animals like us can only rely on self-motivation XD).

The same is first from the construction drawings, and then to the bill of materials.

construction drawing

The verification steps are as follows:

- Check whether the lap length standard is correct

- Check the lap length

- Check the number of main bars

- Check the number of lumbar tendons

- Check stirrup count

Check whether the lap length standard is correct

In this example, in the case of #8 steel bar, fy=4200kgf/cm2, fc'=210kgf/cm2, and stirrup fy=2800kgf/cm2, the lap length of the top steel bar is 261cm in comparison. The connecting length is 265cm, which is qualified.

Check the lap length

In the construction drawings drawn by cad, the lap length is usually drawn according to the actual scale. You can use the dimension to check whether the length is correct.

Here's a digression. The charging method for steel rebar picking is calculated in tons, which is almost 100~200 per ton. According to the difficulty of the case, there will be different unit prices. Sometimes they will not know whether it is intentional or not. If you accidentally pick up a little more lap length, the cost will rise. If the boss has money, there is no problem. If the boss pays attention to the cost, this should be paid attention to.

Picking 265 in 261 cm is not deliberately picking up too much. The steel bar processing factory can only produce materials with the end of 0, such as 700cm, 750cm, 830cm.

Check the number of main bars

The number of main bars in the construction drawing must be the same as that on the structural drawing, so it is called construction according to the drawing. In principle, the pickers will put the structural drawing on the construction drawing for reference, so it is very convenient to check, just look up and down.

Check the number of lumbar tendons

In the same way as the main tendons, the following pictures illustrate

Check stirrup count

Different from the main bar and the waist bar, the stirrups need to be calculated before you know whether they are correct or not. Take the example in the picture below, the structure diagram shows that the stirrups are #4 with a spacing of 15cm, then we have to pull out the beam. Length, length 1060cm, 1060/15=70.666, take an integer of 71 pieces, including the starting number and add 1, so there are 72 pieces in total, please refer to the following figure for details:

Bill of Materials

Beam rebar check is the most difficult of all rebars in my opinion, because "Oversized" , from the short 200cm to the most common 1300cm, how many numbers can be written with 0 at the end, I believe you can also imagine, here is a method, you can use EXCEL to automatically calculate, so as not to press the wrong computer, it is a relatively simple method .

However, you still have to come up with the counts on the statistics chart yourself, print the chart, and cross out one after checking one item, which is more accurate.

Epilogue

Sometimes when the owner changes, adds or subtracts, he will need to calculate the steel material. The first step in calculating is to understand how the material is picked up. After all, there are so many things on the construction site, and many times we absorb it. The experience of others is less of what you think of yourself, otherwise you would have dealt with so many things.

Next words: There is a rebar picking course in the market now, which advertises to learn rebar picking skills in one day. If you are interested, you can go to the FB club to search for rebar picking and look for it. I forgot about 8,000 yuan for a class and tens of thousands of yuan. If you don’t want to spend it If you have so much money, you might as well buy the construction drawings of building steel bars and go back to see them. It has the knowledge of picking up steel bars. It’s not too late to spend 400~500 yuan after reading them if you are interested in going to class.

The engineering-related articles I wrote are all organized in this " Engineering Series Articles ", and will continue to be updated in the future, I hope to be helpful to you.

I'm Mr. Engineering, a little engineer working in the construction industry. Construction industry is an industry with very closed information. Most of all experience can only be passed down by the industry. I hope to do my best to share the knowledge and life of the industry with everyone. If you have any questions about the content of the article, please let me know by leaving a message below. If this article can help you answer, please help me clap five times.

Like my work? Don't forget to support and clap, let me know that you are with me on the road of creation. Keep this enthusiasm together!

- Author

- More