在營造業工作的小小工程師。營造業是個資訊很封閉的行業,所有經驗大部分只能靠業內傳承下來,希望盡自己的一點小小心力,把業內的知識及生活分享給大家 ☛ https://engineeringlifetw.com/

[Construction Life] Reinforcement material list check 1-version reinforcement check

Although in the previous article [Construction Life] Reinforcement Bill of Materials - Do you know how to check the Reinforcement Bill of Materials? I briefly mentioned how to do it, but the checking methods of columns, walls, beams and plates are still slightly different. This time, a series of article to explain the order of checking each part.

For a RC structure building, the project of bare steel bars involves the following manufacturers: steel bar construction, steel bar materials and processing, couplers and other manufacturers. Sometimes due to the lack of manpower on the construction site, the director in charge often directly sends the material list sent by the pickers to the steel bar processing plant. Owners who don’t understand the matter may still be able to get through, but when it comes to supervision, it is a disaster. I will use my personal verification steps below to share with you.

Check steps

First of all, my verification method can be used for the construction drawings and bills of materials produced by cad and excel. It is not impossible to correct the hand-painted construction drawings and bills of materials, but it will take a lot of time to convert, so it is not recommended to use My approach to hand drawing will add up.

Here, we need to figure out the order of picking materials first. For picking materials, we must draw construction drawings first, and then integrate the construction drawings into the bill of materials, so we need to check the construction drawings first, and then check the bill of materials after the pickers have corrected them. is the correct number.

construction drawing

There are several steps here:

- Check whether the standard table of extension length and lap length is correct

- Check if the length is correct

- Check if the count is correct

Check whether the standard table of extension length and lap length is correct

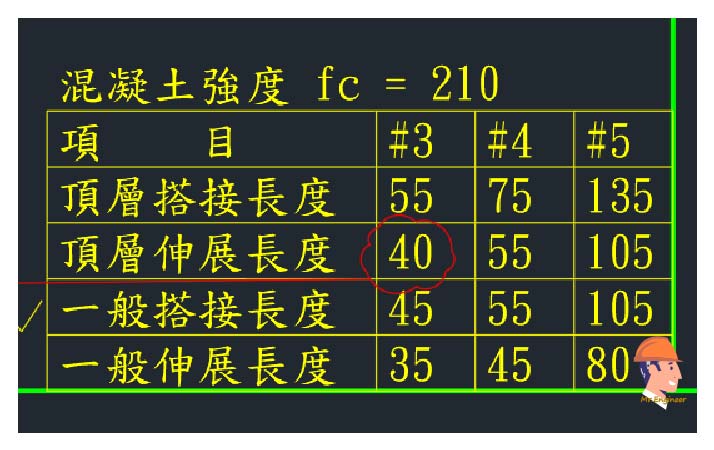

When I get the construction drawing of the rib, the first thing I will look at is: "Is the standard table of extension length and lap length correct?" The construction drawing must be configured according to the structural drawing. If the standard is not correct, there will be a whole group of bad lights in the back.

↑Judging from the above example, the extension length of the #3 steel bar is not enough. Although the extension length of #3 is not needed after the entire plate is assembled, it is still necessary to change it first to avoid problems when it is used in the future.

Check if the length is correct

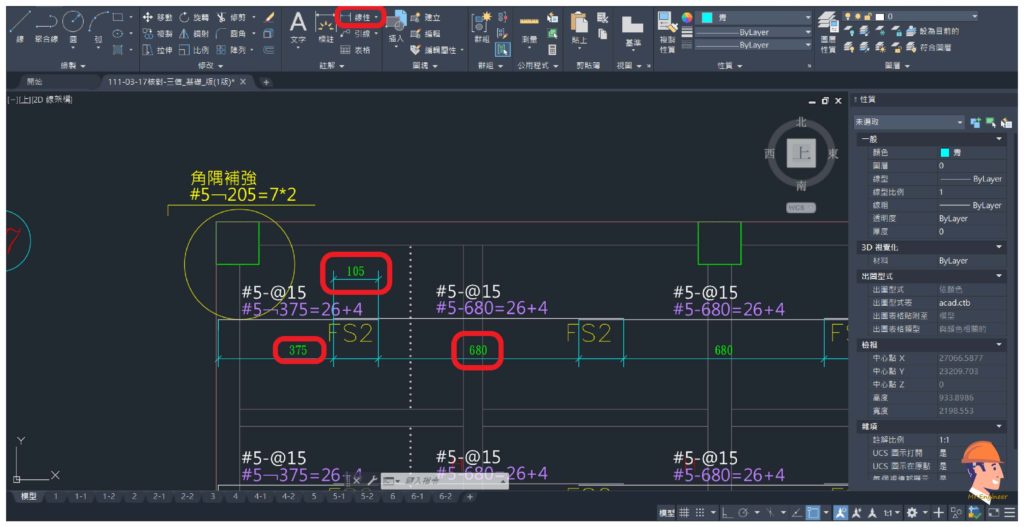

Then use the linear annotations on AutoCAD to mark the size of each section of steel bars. The pickers may not necessarily have the actual length of each section. For example, if the text is 640, the measurement is only 630. It doesn't matter, this is just for the type of material A little less, and the lap length is enough.

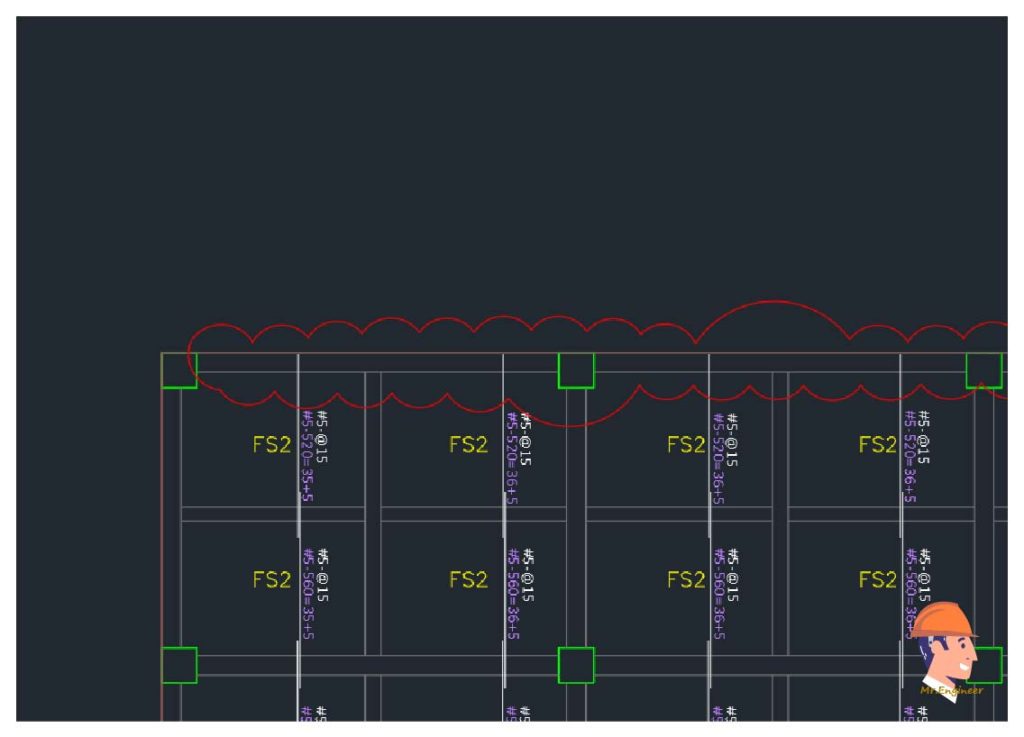

Another more common mistake is: not picking up the hook, and there is no hook at the edge of the rib.

In fact, if the extension length is sufficient, it does not matter if the hook is not used. However, this is the case. However, the extension length required for the large number of steel bars of the raft base plate is very long, and there is no way to meet the standard without picking up the hook.

The length specification of the hook is 12 times the diameter of the steel bar, and the pickers rarely pick up the wrong thing, so they don't need to pay special attention. Mainly after picking up the hook, the standard watch shows the anchoring length. The value will be much shorter than the extension length. Usually, it can be satisfied. If it still cannot be satisfied, ask the structural technician to clarify the doubt. The most general solution should be The beam is wide and the building is added, but this rarely happens, so there is no need to worry.

↑ Mark the length of each steel bar linearly, and check whether the lap length is enough by the way.

↑As in the example in the picture above, there is no hook on the edge of the steel bar. It is not enough to calculate the extension length of the #5 steel bar, so we need to pick up the hook.

Check if the count is correct

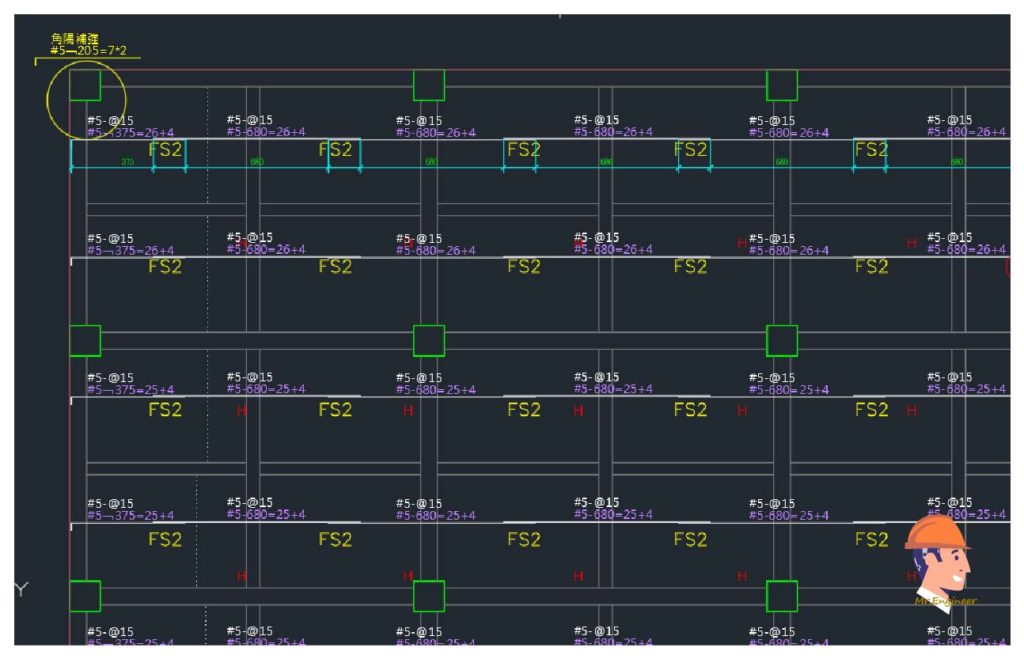

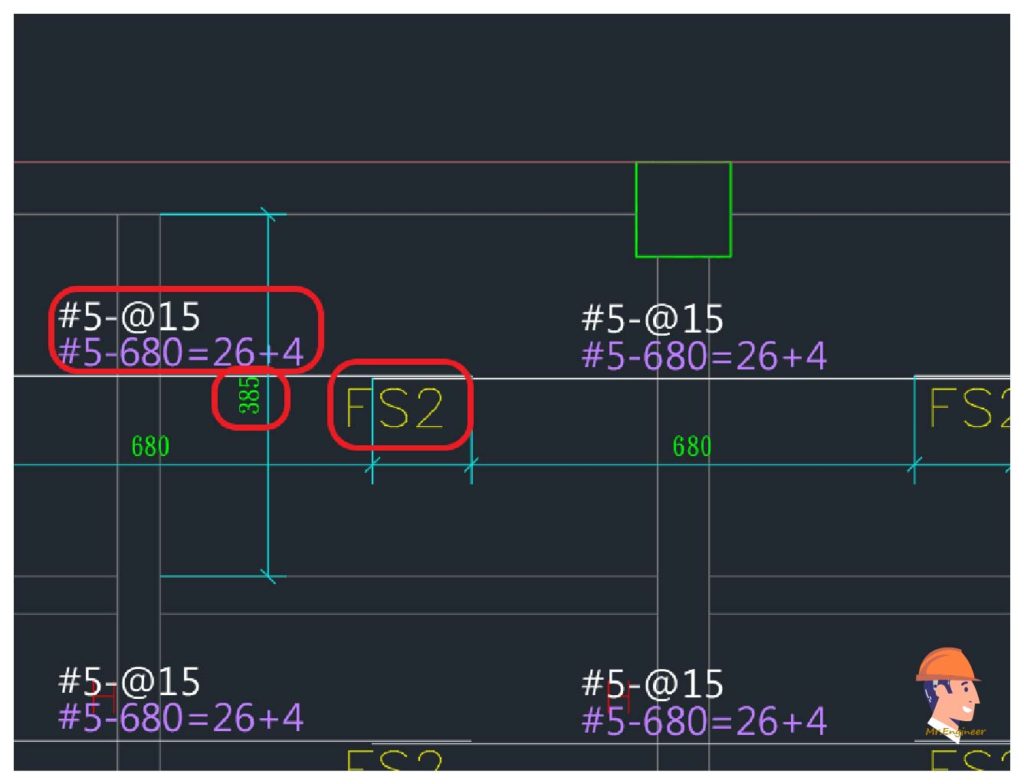

In the part of the number of counts, a step is actually missed, which is to check whether the spacing of the ribs is the same as the spacing on the structure diagram, but it does not matter, it can be carried out simultaneously. First, check whether the spacing of the structure diagram of the version number comparison is correct with the number of numbers. Then calculate the number of rods. The calculation method is unconditional rounding. For example, the reinforcement distance is 385cm, the distance between the reinforcement bars is 15cm, 385/15=25.6667, and the unconditional rounding is 26, and the final result is 26.

↑The last number on the picture is 26+4. The reason for the +4 is the working reinforcement. The reinforcement pads on the bottom layer of the board are 1 meter and 1 piece. If you calculate this part, the final reinforcement will not be enough. This is the experience of picking up materials. Novices will pick up materials differently.

The next step is to keep repeating the above steps. It is best not to be disturbed by other work when checking the bill of materials. You will easily mess up. If you forget where you are right halfway, everything will have to be done all over again, so before you start, tell you Colleague, don't disturb you yet.

Bill of Materials

The steps of the bill of materials are relatively simple, and there is no need to judge too much. Just copy the length, shape and count, and add them up to see if they are correct. I don’t know if there is a program that can automatically add up this part. Ask the pickers and share with you.

You can use EXCEL for the summed part. You don't need to press the computer yourself. Pressing the computer is easy to make mistakes. EXCEL can automatically calculate it for you.

Epilogue

Regarding the construction quality of steel bars, it is necessary to control the construction drawing step. If there is no problem with the construction drawing, there will be fewer problems on site. Whether the construction site is managed or not, I personally think it is the poor place. There is a saying in the construction industry, called " natural " Completion method ", which means that the work class is called to do it, and it doesn't matter whether the work is good or bad, so you have the nerve to charge the " management fee " with the owner? It's my word, I dare not.

Next words: There is a rebar picking course in the market now, which advertises to learn rebar picking skills in one day. If you are interested, you can go to the FB club to search for rebar picking and look for it. I forgot about 8,000 yuan for a class and tens of thousands of yuan. If you don’t want to spend it So many years ago, you might as well buy the construction drawings of building steel bars and go back to see them. It has the knowledge of how to pick up steel bars. It’s not too late to spend 400~500 yuan to read them and then go to class if you are interested.

I'm Mr. Engineering, a little engineer working in the construction industry. Construction industry is an industry with very closed information. Most of all experience can only be passed down by the industry. I hope to do my best to share the knowledge and life of the industry with everyone. If you have any questions about the content of the article, please let me know by leaving a message below. If this article can help you answer, please help me clap five times.

The engineering-related articles I wrote are all organized in this " Engineering Series Articles ", and will continue to be updated in the future, I hope to be helpful to you.Like my work?

Don't forget to support or like, so I know you are with me..

Comment…